LG Energy Solution Wrocław

LG Energy Solution Wrocław is the largest plant producing batteries for electric cars in Europe. An over 100-hectare, state-of-the-art technology park is located in Biskupice Podgórne near Wrocław, where several thousand people, representing over a dozen nationalities, work.

The company produces 700,000 EV batteries per year, and the

company’s goal is to produce one million batteries for electric cars per year.

The current production capacity is 86 GWh.

The factory near Wrocław produces batteries that power cars of the world’s leading brands such as:

- Audi,

- BMW,

- Fiat,

- Ford,

- Porsche,

- Volkswagen.

Advanced Automotive Business Area

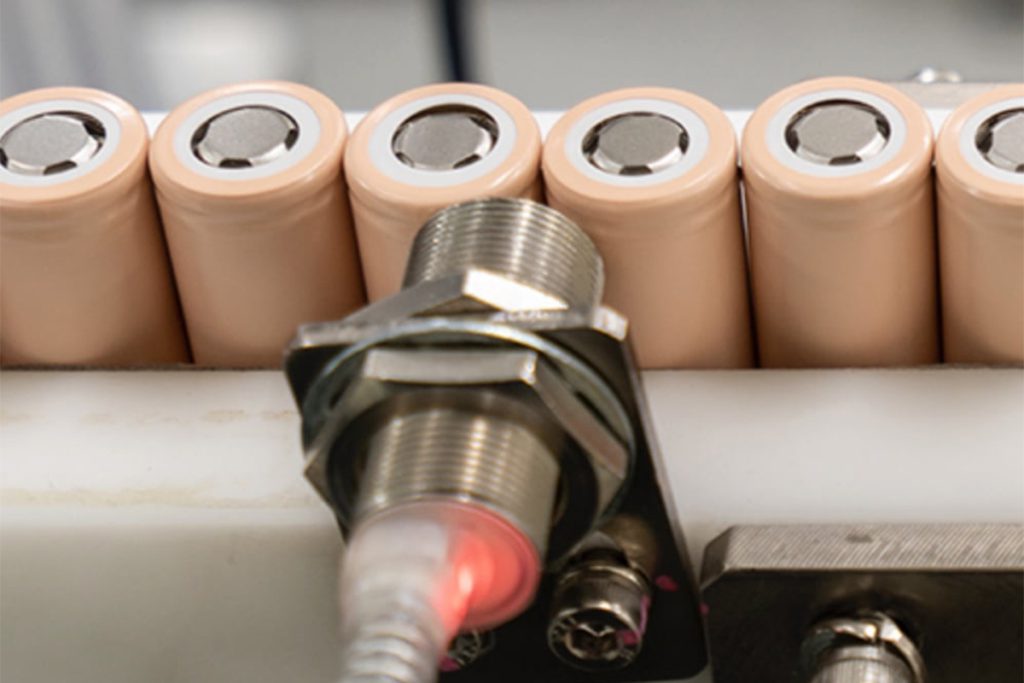

Production of lithium-ion batteries for EV cars

Year Founded

2016President

Sang Hun LeeArea

107 haInvestment Cost

USD 5 billion [2022]Production Capacity

86 GWh [2022]Target Capacity

90 GWh [2025]LG Energy Solution Wrocław was established in 2016 in Biskupice Podgórne. The greenfield investment in Wrocław has resulted in the introduction of state-of-the-art technology to Poland, as well as making our country a European leader in the industry. The plant, which occupies an area of around 100 hectares, houses dozens of modern production lines.

Founding of LG Chem:

the beginning of the LG Group

Research on lithium-ion batteries

Mass production of cylindrical lithium-ion batteries

First shipment of mass-produced batteries

Start of investment in Poland

Completion of factory in Poland

Spin-off of LG Energy Solution

Change of name to

LG Energy Solution Wrocław

Increase in production capacity

The history of LG Energy Solution began in 1947 with the establishment of the Korean company Lucky Chemical – initially a cosmetics manufacturer. Thanks to continuous growth and the constant expansion of its business portfolio, the company has been listed on the Korean Stock Exchange since 1969.

Over the following decades, the company opened further production centres and entered new markets – including plastics. In 1995, the company changed its name to LG Chem.

The conglomerate began researching lithium-ion (Li-Ion) batteries back in 1992 and development work on them in 1996. Mass production of cylindrical lithium-ion batteries began in 1999.

The start of our group’s development work on Li-Ion batteries for the automotive industry dates back to 2000. Less than 10 years later – in the second half of 2009 – LG Chem was the first ever to supply this type of battery for hybrid electric vehicles (HEVs) to Hyundai Motors. In the same year, our concern became the exclusive battery supplier to General Motors, which was then planning to launch mass production of the world’s first electric car, the Chervolet Volt.

The contracting of further customers and the dynamic growth of the industry necessitated an increase in the group’s production capacity. Back in 2009, construction of a battery plant in Ochang, Korea, began, a year later in Michigan, USA, and in 2014 in Nanjing, China. In October 2016, construction of a factory in Biskupice Podgórne, near Wrocław, Poland, began.

In 2019, our group established a joint venture with General Motors – Ultium Cells. Currently, a second plant is being built in the United States to produce cells for electric vehicles under this brand.

December 2020 brought changes at Group level, resulting in the spin-off of the battery industry from LG Chem to the newly formed LG Energy Solution, currently headed by Young Soo Kwon.

In July 2021, a cooperation agreement was announced with Hyundai Motor Group. Under this agreement, the two Groups will jointly invest USD 1.1 billion in the construction of a plant for the production of cells to be used in electric cars of the Hyundai and Kia brands. The new production centre will be built in Karawang, Indonesia. Production is scheduled to start in the first half of 2024.

In October 2021. LG Energy Solution and Stellantis Concern reached an agreement to establish a joint venture. Its aim will be to produce cells and modules for the North American automotive market. The parties intend to build a new factory with an annual production capacity of 40 GWh. The plant is scheduled to be operational in the first quarter of 2024. Batteries produced there will be supplied to Stellantis assembly plants in the US, Canada and Mexico. The conglomerate owns automotive brands such as: Alfa Romeo, Fiat, Jeep, Maserati, Opel and Peugeot.

LG Energy Solution

12/2020

foundation date

34 200

employees

$20,2 B

revenue [2020]

90 000+

number of patents

Areas

Advanced Automative • IT • ESS

President

Dong Myung Kim

Production Facilities

South Korea, Poland, China, U.S.A.

Joint Ventures

GM, Stellantis, Hyundai Motor Group, Ford, Honda Motor Co.

Today, LG Energy Solution is a global leader supplying batteries to all market segments: from consumer products in the IT and power tool sectors, to the advanced automotive industry – supplying 13 of the world’s top 20 automotive brands – to energy storage systems (ESS).

With 30 years of experience in revolutionary battery technology and extensive research and development (R&D), the company is also the largest holder of battery-related patents in the world.

Its strong global network includes battery production facilities established in joint ventures with major car manufacturers such as General Motors, Stellantis N.V., Hyundai Motor Group and Honda Motor Co. etc., spread across North America, Europe, Asia and Australia.

By taking eco-friendly measures and supporting sustainability, LG Energy Solution aims to achieve carbon neutrality by 2050, while adhering to the value of shared growth and promoting a diverse and inclusive corporate culture.